Solar Energy Organic-hybrid electronics Laboratory

104

Tilted-Oriented 2D Perovskites for High-Performance Solar Cells

Chanhyeok Kim, Dong Gyu Lee, Youngmin Kim, Jinsoo Park, Kihoon Kim, Jaehun Kim, Jaehee Lee, Seungjin Lee, Jangwon Seo, Nam Joong Jeon, Jaeki Jeong, Bong Joo Kang, Tae Kyung Lee, Hanul Min

Advanced Energy Materials

Abstract

Despite the high stability of 2D perovskites, high-efficiency perovskite solar cells (PSCs) have predominantly been fabricated using pure 3D perovskites as the light-absorbing layer. Introducing 2D perovskites into the 3D perovskite bulk typically leads to the formation of insulating spacer layers between conductive inorganic slabs, limiting the conductivity and charge transport of the 3D perovskite, thereby reducing device efficiency. This study demonstrates that these disadvantages associated with introducing 2D perovskites can be eliminated by tilting the 2D perovskite orientation. The thermodynamically stable tilted 2D perovskite orientation enhances the conductivity of 3D perovskites, improves film uniformity, and reduces defect concentration through grain boundary passivation. Additionally, the method used to induce this tilted 2D perovskite orientation does not influence the crystallization process of the highly optimized 3D perovskite. As a result, the best-performing PSCs exhibit an efficiency of 26.6% (certified efficiency of 26.3%) under simulated solar illumination. Furthermore, encapsulated devices retain ≈90% of their initial efficiency even after 1100 h of operation under maximum power point tracking. These findings provide critical insights into overcoming the inherent limitations of conventional 2D perovskites, offering a pathway toward high-efficiency and stable PSCs.

Abstract

Perovskite solar cells are emerging as promising candidates for next-generation solar cells and are being extensively researched due to their rapidly increasing power conversion efficiency. However, high-efficiency perovskite solar cells typically use expensive metals such as gold and silver as electrodes, which undermines their cost advantage and limits their applicability due to the complexity of the deposition processes. To address these challenges, researchers have attempted to use carbon film electrodes; however, their performance generally falls short compared to metal counterparts. In this study, we incorporated a self-assembled hole-selective bilayer into a conventional n-i-p perovskite solar cell with a free-standing carbon electrode, enhancing interfacial contact and promoting efficient hole extraction to the carbon electrode. The resulting device exhibited a higher power conversion efficiency of 24.25%, enhanced stability, and improved reproducibility compared to the control device.

Abstract

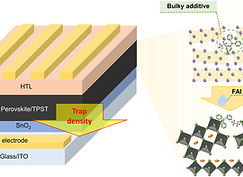

We incorporated triphenylsulfonium triflate (TPST), a sulfonium-based additive consisting of polar triflate and bulky hydrophobic phenyl rings, to the PbI2 precursor solution for preparation of less-defect perovskite film via two-step fabrication. TPST induced localized alterations in the array of the PbI2 structure due to its large size, thereby forming a more discontinuous and coarser surface with a greater number of pinholes and subsequently facilitating more efficient organic–inorganic reactions. As a result, we achieved the production of thick perovskite films with enlarged granules and decreased PbI2 residuals in the two-step fabrication process. Furthermore, TPST facilitated the passivation of bulk film defects by increasing the binding energy with the defects. Consequently, the ITO/SnO2 np-based device and the FTO/CBD SnO2-based device obtained the best PCEs of 23.88% and 24.30%, respectively. Furthermore, the moisture stability of the perovskite was improved by the hydrophobic character of the TPST additive.

Abstract

Despite the notable advancements in perovskite photovoltaic technology, the performance and stability of flexible perovskite solar modules (f-PSMs) fall behind commercial standards. Conventional colloidal SnO2 electron transport layer (ETL) creates an efficiency-stability trade-off in flexible perovskite solar cells (f-PSCs). The developed multi-layer (ML) ETL resolves this trade-off by improving the surface coverage without scarifying the charge-transporting property and enables efficiencies of 22.9% on f-PSCs (0.1 cm2) and 16.4% on f-PSMs (900 cm2). In addition, the ML ETL improves the operational stability of f-PSM.

Abstract

For the last decade, perovskite solar cells have been in rapid growth, highlighted as a representative next-generation solar cell. Although SnO2 is suitable as the electron-transporting material of perovskite solar cells, there also have been some obstacles in the formation of uniform and thin layers of SnO2 on the uneven FTO substrate. In this work, we investigated polymer-assisted fabrication methods to achieve conformal coating of SnO2 nanoparticles on rough FTO substrate, finally leading to improved performance of perovskite solar cells due to enhanced coverage and optimized electron-transporting property. As a result, we fabricated an efficient perovskite solar cells with a power conversion efficiency of 24% by employing polymer-capped SnO2 nanoparticles as electron-transporting layer.

Abstract

In this review, p-type doping technologies for organic/polymeric semiconductors in hole transporting layer (HTL) for perovskite solar cells (PSCs) are examined. Initially, we investigate the conventional dopant systems used for HTL in terms of dopants and additives, as well as their doping principles and limitations. Second, we recapitulate the current research strategies for overcoming the limitations of conventional dopant systems: (i) dopants/additives with large cations, (ii) hydrophobic dopants/additives, (iii) locking-capable dopants/additives, (iv) rinsing or ion exchange methods, and (v) other methods. Afterwards, we provide a comprehensive analysis of alternative dopants based on ionic liquids, Lewis acids, strong acceptors, and others. In addition, the review emphasizes current achievements based on multiple research approaches to diverse hole transporting materials, surface/interfacial treatment, and architectural modification of HTL, and provides a perspective on developments of desirable HTL system for efficient and stable PSCs.

Abstract

The power conversion efficiency (PCE) of perovskite solar cells (PSCs) has been renewed annually, now recorded to 25.7%, which is the highest efficiency for thin-film solar cells, raising expectations for commercialization. However, the PSCs have a massive technical lack in entering the photovoltaic industry because of the low PCE of perovskite solar modules (PSMs), poor stability, high levelized cost of energy (LCOE), and environmental issues. Herein, cutting-edge studies for overcoming the challenges faced by commercialization of PSCs are discussed. First, the reduction of the efficiency gap between small-area PSCs and the large-area PSMs via the solution process is reviewed. Second, the strategies for stable PSMs are discussed to reduce the LCOE. In addition, the environmental issues for manufacturing and sustainable use of PSMs are dealt with and it is demonstrated that the recycling/reuse of PSMs is the most promising way to reduce the manufacturing costs. Finally, it is suggested that the life cycle assessment system from manufacturing to recycling/reuse for PSMs is the key technology to resolve the commercialization issues of PSCs.

97

Suppression of Undesired Losses in Organometal Halide Perovskite-Based Photoanodes for Efficient Photoelectrochemical Water Splitting

Hojoong Choi, Young Yun Kim, Sehun Seo, Yoonsung Jung, So-Min Yoo, Chan Su Moon, Nam Joong Jeon, Sanseong Lee, Kwanghee Lee, Francesca M. Toma, Jangwon Seo, Sanghan Lee

Advanced Energy Materials

Abstract

Organometal halide perovskites (OHPs) have become potential candidates for high-efficiency photoelectrodes for use in photoelectrochemical (PEC) water splitting. However, undesired losses, such as the non-radiative recombination of photogenerated carriers and sluggish reaction kinetics of PEC water splitting, are the main limitations to achieving maximum efficiency for OHP-based photoelectrodes. Herein, high-efficiency OHP-based photoanodes with a rational design that suppresses the undesired losses is reported. As a rational design for OHP-based photoanodes, the defect-passivated electron transport layers effectively suppress the undesired recombination of photogenerated carriers from the OHP layers. In addition, Fe-doped Ni3S2 with a high catalytic activity promotes the reaction kinetics of PEC water oxidation, thereby suppressing the undesired losses at the interface between the OHP photoanodes and electrolytes. The fabricated Fe-doped Ni3S2/Ni foil/OHP photoanodes exhibit a remarkable applied bias photon-to-current efficiency of 12.79%, which is the highest of the previously reported OHP-based photoanodes by suppressing undesired losses. The strategies for achieving high-efficiency OHP-based photoanodes provide insights into the rational design of photoelectrodes based on OHPs.

Abstract

The important but remained issue to be addressed to achieve the mass production of perovskite solar modules include a large-area fabrication of high-quality perovskite film with eco-friendly, viable production methods. Although several efforts are made to achieve large-area fabrication of perovskite, the development of eco-friendly solvent system, which is precisely designed to be fit to scale-up methods are still challenging. Herein, this work develops the eco-friendly solvent/co-solvent system to produce a high-quality perovskite layer with a bathing in eco-friendly antisolvent. The new co-solvent/additive, methylsulfonylmethane (MSM), efficiently improves the overall solubility and has a suitable binding strength to the perovskite precursor, resulting in a high-quality perovskite film with antisolvent bathing method in large area. The resultant perovskite solar cells showed high power conversion efficiency of over 24% (in reverse scan), with a good long-term stability under continuous light illumination or damp-heat condition. MSM is also beneficial to produce a perovskite layer at low-temperature or high-humidity. MSM-based solvent system is finally applied to large-area, resulting in highly efficiency perovskite solar modules with PCE of 19.9% (by aperture) or 21.2% (by active area) in reverse scan. These findings contribute to step forward to a mass production of perovskite solar modules with eco-friendly way.

Abstract

Perovskite solar cells (PSCs) have the potential to produce solar energy at a low cost, with flexibility, and high power conversion efficiency (PCE). However, there are still challenges to be addressed before mass production of PSCs, such as prevention from degradation under external stresses and the uniform, large-area formation of all layers. Among them, the most challenging aspect of mass production of PSCs is creating a high-quality perovskite layer using environmentally sustainable processes that are compatible with industry standards. In this review, we briefly introduce the recent progresses upon eco-friendly perovskite solutions/antisolvents and film formation processes. The eco-friendly production methods are categorized into two: (1) employing environmentally friendly solvents for perovskite precursor ink/solution, and (2) replacing harmful, volatile antisolvents or even limiting their use during the perovskite film formation process. General considerations and criteria for each category are provided, and detailed examples are presented, specifically focused on the works have done since 2021. In addition, the importance of controlling the crystallization behavior of the perovskite layer is highlighted to develop antisolvent-free perovskite formation methods.

94

Alkylammonium bis(trifluoromethylsulfonyl)imide as a dopant in the hole-transporting layer for efficient and stable perovskite solar cells

Youngwoong Kim, Geunjin Kim, Eun Young Park, Chan Su Moon, Seung Joo Lee, Jason J. Yoo, Seongsik Nam, Jino Im, Seong Sik Shin, Nam Joong Jeon, and Jangwon Seo

ENERGY & ENVIRONMENTAL SCIENCE

Abstract

In state-of-the-art n-i-p structured perovskite solar cells (PSCs), a dopant for doping hole transporting materials (HTMs) is a crucial component, which affects not only the electrical properties of HTMs, but also the performances and stabilities of PSCs. In this paper, we report new dual functional ionic liquids (ILs) consisting of various alkylammoniums (from butyl to decyl) and bis(trifluoromethylsulfonyl)imide (denoted as BATFSI, HATFSI, OATFSI, and DATFSI) as a dopant and surface passivator for highly efficient and stable PSCs and modules. Among these ILs, OATFSI provides enough miscibility with a poly(triarylamine) solution, which results in a smoother morphology of the hole transporting layer (HTL) with an enhanced electrical property via efficient doping. Simultaneously, OATFSI passivates the perovskite surface in situ, during spin-coating deposition of the HTL. Highly efficient and stable OATFSI-based PSCs are fabricated with a mesoporous n-i-p structure and a maximum power conversion efficiency (PCE) of 23.34%, due to reduced non-radiative recombination and better charge extraction. To verify the scalability of our new IL dopants, perovskite modules with a high PCE of 18.54% (on the aperture area of 224.89 cm(2)) and 19.91% (on the active area of 209.39 cm(2)) are demon...

93

First Demonstration of Top Contact-Free Perovskite/Silicon Two-Terminal Tandem Solar Cells for Overcoming the Current Density Hurdle

Dowon Pyun, Sang-Won Lee, Youngwoong Kim, Gyeong Sun Jang, Dongjin Choi, Seok Hyun Jeong, Hoyoung Song, Solhee Lee, Sujin Cho, Jiryang Kim, Dongkyun Kang, Ha Eun Lee, Ji Yeon Hyun, Changhyun Lee, HyunJung Park, Jae-Keun Hwang, Wonkyu Lee, Nam Joong Jeon, Jangwon Seo, Yoonmook Kang, Donghwan Kim, and Hae-Seok Lee*

ACS APPLIED ENERGY MATERIALS

Abstract

Current density plays a substantial role in monolithic tandem solar cells; however, it is difficult to control because subcells and auxiliary layers are stacked and serially connected vertically to obtain higher voltages. The vertically stacked structure intrinsically triggers inevitable parasitic absorption. In current typical perovskite/silicon two-terminal (2-T) tandem solar cells, 5–10 layers are placed on the light path, even though they are not current generating layers. These layers usually include transparent window layers, buffer layers, carrier extraction layers, and recombination layers. Therefore, the development of top contact-free architectures to reduce parasitic absorption in 2-T tandem solar cells is required for achieving high efficiency. In this study, a top contact-free perovskite/silicon 2-T tandem solar cell with quasi-interdigitated intermediate electrodes (Q-IDIEs) is reported for the first time. Several layers placed above the perovskite layer in conventional devices are relocated to the backside of the perovskite. The Q-IDIE, composed of a patterned Ni/NiOX shell above the full-deposited TiO2, was fabricated by the following processes: photolithography, lift-off, and oxidation. The device results in 4.23% efficiency with an open-circuit voltage of 1.54 V. This tandem architecture is expected to be a breakthrough for overcoming the theoretical efficiency limit of single-junction solar cells with further optimization.